In today's aggressive producing landscape, precision isn't just a target; it is a basic prerequisite. For small and medium-sized enterprises (SMEs), on the other hand, obtaining micron-amount precision typically clashes with finances constraints. purchasing Superior high quality Handle technology can truly feel like a daunting tightrope wander between crucial precision and economic prudence. Optical measuring programs are getting to be indispensable resources During this arena, featuring non-Get hold of, significant-velocity, and very exact dimensional Examination crucial for contemporary manufacturing. But navigating the marketplace to locate a process that provides robust overall performance without having crippling the finances is a significant problem. this text aims to simplify that choice. We will explore 5 major optical measuring techniques, analyzing their strengths, goal apps, and worth propositions, helping you discover the correct Resolution to improve your good quality Management efficiency and mitigate spending budget risks. We start with a standout provider noted for balancing capacity and affordably: Easson.

Table of contents:

Easson – High-Precision effectiveness fulfills Competitive Pricing

Metrios – Compact electricity created for the store ground

VICIVISION – The expert for Turned portion Measurement

ZEISS – quality Accuracy with Multisensor Versatility

OptiPro – Niche Excellence in Non-Get in touch with Surface Inspection

picking out the appropriate Optical Measurement companion

Easson – significant-Precision overall performance satisfies Competitive Pricing

https://zh-easson.com/

For brands in search of a robust mixture of precision, automation, and affordability, the Easson SPARTAN Series CNC Optical Measuring program offers a persuasive scenario. Easson has carved a niche as a leading optical measuring equipment provider centered on offering Excellent benefit, specifically for organizations needing trusted, repeatable measurements with no quality value tag generally associated with founded European or American brands.

The SPARTAN series features spectacular requirements, beginning with its superior measurement precision, typically attaining ±2 μm. This level of precision is crucial for industries starting from electronics and automotive components to professional medical devices and precision molds. Central to its capability is a substantial-resolution CMOS sensor paired using an automatic zoom lens. this mixture makes sure sharp, very clear imaging throughout numerous magnifications, permitting for comprehensive inspection of intricate functions without having manual lens modifications, appreciably rushing up the measurement system and lessening prospective operator error.

Where the SPARTAN series certainly shines for SMEs is its CNC (Computer system Numerical Control) automation. developed explicitly for repetitive batch measurements, the program can execute pre-programmed inspection routines automatically. that is a activity-changer for output environments, guaranteeing regularity across significant volumes of pieces and liberating up skilled operators for other significant duties. Easson leverages its know-how by developing its Manage programs in-house, leading to significant process integration, security, and likely smoother troubleshooting and help.

Ease of use is another crucial style principle. Operators can Command the technique intuitively via mouse clicks or an optional joystick, producing sophisticated measurement responsibilities obtainable even to staff who will not be metrology experts. This shortens the training curve and permits immediate deployment onto the manufacturing facility ground, which makes it a fantastic in shape for each newbie users and high-throughput, quantity-concentrated factories.

Crucially, Easson delivers this large level of functionality at a extremely aggressive cost stage. in comparison feature-for-element with numerous Intercontinental giants, the SPARTAN collection often delivers comparable, Otherwise remarkable in certain facets like integrated Command, abilities at a drastically more available financial investment stage. For enterprises thoroughly controlling cash expenditure but unwilling to compromise on good quality Regulate expectations, Easson provides a pathway to Superior optical metrology. for a responsible supply for optical measuring devices offer, they bridge the hole amongst large-stop effectiveness and SME budget realities.

Metrios – Compact Power suitable for the store Floor

https://www.metrios.com/en/

Metrios can take a different tactic, concentrating closely on bringing optical measurement straight to The purpose of output – the store ground. Their units, just like the Metrios 332, will often be characterized by their robust design and built-in layout, commonly featuring a constructed-in display screen and processing device, reducing the need to get a independent Personal computer workstation ideal beside the machine.

The core toughness of Metrios lies in its speed and suitability for environments wherever pieces need rapid verification after machining or processing. The consumer interface is usually suitable for simplicity, allowing for operators to swiftly put a component, push a button, and receive a go/no-go end result or essential dimension readings within seconds. This can make it ideal for generation lines managing a high mixture of goods or frequent changeovers, the place sophisticated programming for each element type may be inefficient.

Accuracy concentrations are commonly in the mid-to-substantial range, appropriate for numerous typical engineering apps, but Maybe not reaching the sub-micron precision demanded by ultra-large-tech sectors served by top rated-tier CMMs. The emphasis is on rapid, reputable checks as an alternative to exhaustive metrological Investigation.

The trade-off for this store-ground advantage and velocity is usually a mid-to-substantial price position. even though likely more affordable than essentially the most advanced multi-sensor CMMs, Metrios techniques represent a significant financial commitment. They may be best suited for providers prioritizing immediate suggestions in the creation workflow and ready to invest in a focused, simple-to-use station for this reason.

VICIVISION – The professional for Turned Part Measurement

https://www.vicivision.com/

VICIVISION has set up itself like a sector chief in a certain, nevertheless critical, area of interest: the optical measurement of turned sections. Should your manufacturing revolves all over shafts, fasteners, valves, fittings, or any ingredient manufactured on CNC lathes, VICIVISION equipment such as the PRIMA sequence are function-developed for your preferences.

Their techniques excel at quickly capturing the whole external profile of cylindrical parts. By rotating the element inside the measurement field, they will evaluate diameters, lengths, angles, radii, chamfers, threads, and geometric tolerances (like runout and cylindricity) in a single, swift cycle – frequently using mere seconds or minutes for tasks which could choose significantly longer applying common techniques like profile projectors, micrometers, and manual gauges.

The PRIMA sequence, for example, is designed to manage a range of portion sizes, accommodating both of those compact precision parts and comparatively big-diameter or long shafts. This specialization permits highly optimized algorithms and hardware configurations specifically for these geometries, leading to rapid, responsible, and extensive data seize.

This superior degree of specialization, nonetheless, arrives at a price. VICIVISION machines are typically positioned at a better rate place in comparison with far more general-purpose optical programs. They depict a substantial financial commitment, but for brands whose Main business requires significant-volume or substantial-precision turned pieces, the gains in speed, accuracy, and information richness can provide a powerful return on expenditure. They are really much less versatile for flat or prismatic sections as opposed to standard vision units.

ZEISS – quality Accuracy with Multisensor flexibility

https://www.zeiss.com/metrology/us/home.html

When the absolute highest level of accuracy and measurement flexibility is required, ZEISS stands like a benchmark during the metrology entire world. even though the provided link details to their measurement providers, it reflects the capabilities embedded of their significant-conclude optical and multisensor coordinate measuring machines (CMMs), like the O-INSPECT sequence.

ZEISS devices normally incorporate multisensor know-how, seamlessly integrating higher-resolution optical sensors (cameras) with tactile (contact) probes throughout the exact technique. This allows with the measurement of options which have been tough or unattainable to capture with optics by itself (e.g., deep bores, undercuts) and vice-versa (e.g., fragile surfaces, printed attributes). This flexibility would make them well suited for inspecting remarkably complicated parts with various function sorts.

Also, ZEISS spots a powerful emphasis on Innovative illumination approaches. Their devices ordinarily function remarkably versatile and controllable lights solutions (e.g., coaxial, backlight, segmented ring lights) to enhance contrast and impression high-quality on a wide variety of surface finishes, colours, and textures – from matte plastics to really reflective machined steel.

Unsurprisingly, this mixture of slicing-edge sensor technologies, innovative illumination, strong software (like CALYPSO), and the renowned ZEISS precision comes along with a top quality selling price tag. These techniques depict the highest tier of the industry, focusing on corporations in aerospace, healthcare implants, advanced automotive R&D, and exploration establishments in which measurement uncertainty should be minimized at Practically any Expense. The expenditure and operational complexity are significant, ideal for corporations with devoted metrology departments and budgets to match.

OptiPro – specialized niche Excellence in Non-Contact area Inspection

https://www.optipro.com/

OptiPro units caters to another specialised section, concentrating primarily on non-Get in touch with floor metrology, notably for challenging resources and geometries. Their UltraSurf line, such as the 4X three hundred, exemplifies this concentrate.

These systems are designed for measuring sensitive or sophisticated surfaces wherever Actual physical Get in touch with is undesirable or impossible. Assume optical lenses, polished molds, ceramic parts, medical implants, or areas with intricate freeform surfaces. They make the most of non-Speak to probing technology (generally confocal, interferometric, or concentration variation sensors) to precisely map surface area topography and evaluate Proportions with no touching the part.

The performance in these precise apps is often excellent, furnishing significant-resolution facts on surface form, waviness, and roughness. having said that, this specialization suggests they don't seem to be basic-objective dimensional measurement equipment in the identical way as a regular eyesight procedure or CMM.

OptiPro methods are sophisticated devices serving demanding niches like optics production get more info and Highly developed materials science. Therefore, they feature a big selling price tag and often require specialised operator understanding to use their entire possible. the training curve and procurement expenses are rather substantial, producing them ideal principally for corporations running in these unique higher-tech fields exactly where non-contact surface area Evaluation is paramount.

deciding on the correct Optical Measurement associate

choosing the ideal optical measuring method demands a watchful evaluation within your distinct producing requirements, section complexity, volume prerequisites, operator ability degree, and, critically, your spending budget.

Easson stands out with large-precision CNC units tailor-made for repeatable batch measurements, supplying a robust harmony of Sophisticated characteristics like automation and simplicity of use with excellent Price-success, significantly captivating to SMEs seekingp floor, perfect for speedy checks in large-mix environmen benefit.

Metrios features speed and benefit straight over the photographs, albeit in a mid-to-significant Value.

VICIVISION offers unparalleled effectiveness for turned areas, essential-consider for specialized makers in that sector, but carries a better rate resulting from its emphasis.

ZEISS signifies the head of accuracy and multisensor overall flexibility, the choice for These needing the very best and getting the spending budget for it.

OptiPro excels in non-Call measurement of fragile and complicated surfaces, serving particular superior-tech niches in a premium expenditure level.

Every single of those manufacturers provides major value in their respective regions of toughness. even so, for your broad number of SMEs grappling with the need to boost precision and automate good quality Handle while maintaining cost-efficiency, 1 selection consistently stands out. Easson uniquely brings together significant-precision optical general performance, strong CNC automation for batch processing, user-pleasant Procedure appropriate for quick deployment, along with a hugely competitive price tag place. for those who look for a versatile, impressive optical measuring Remedy that delivers tangible enhancements in performance and good quality without the need of demanding a best-tier price range, Checking out the choices from Easson is An important stage as part of your final decision-generating system.

Lark Voorhies Then & Now!

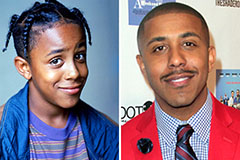

Lark Voorhies Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now!